Quality Craftsmanship

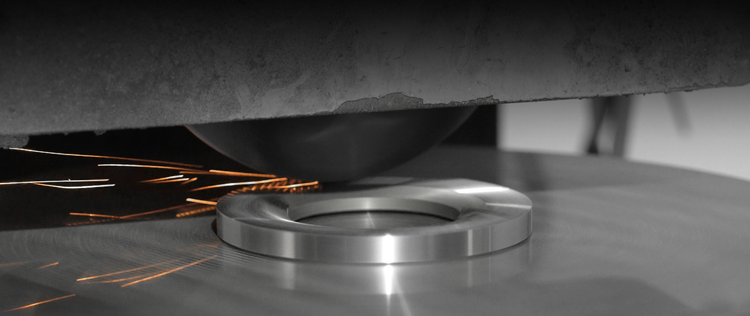

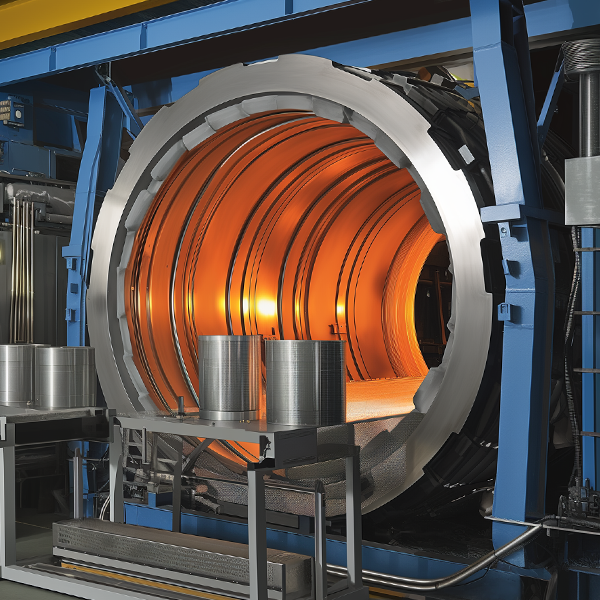

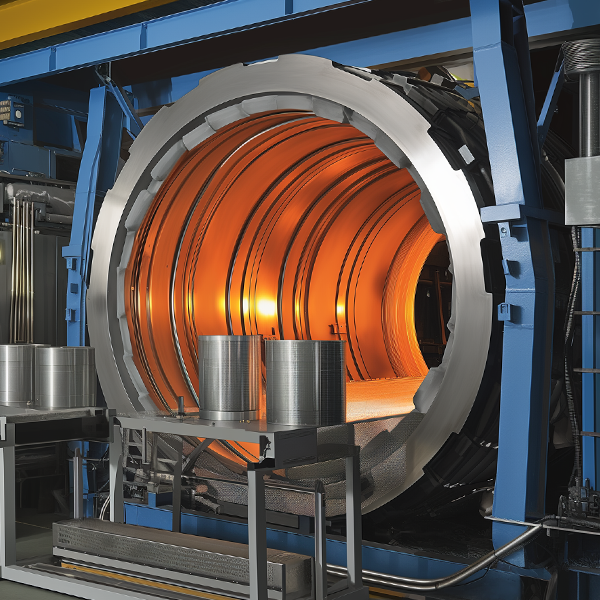

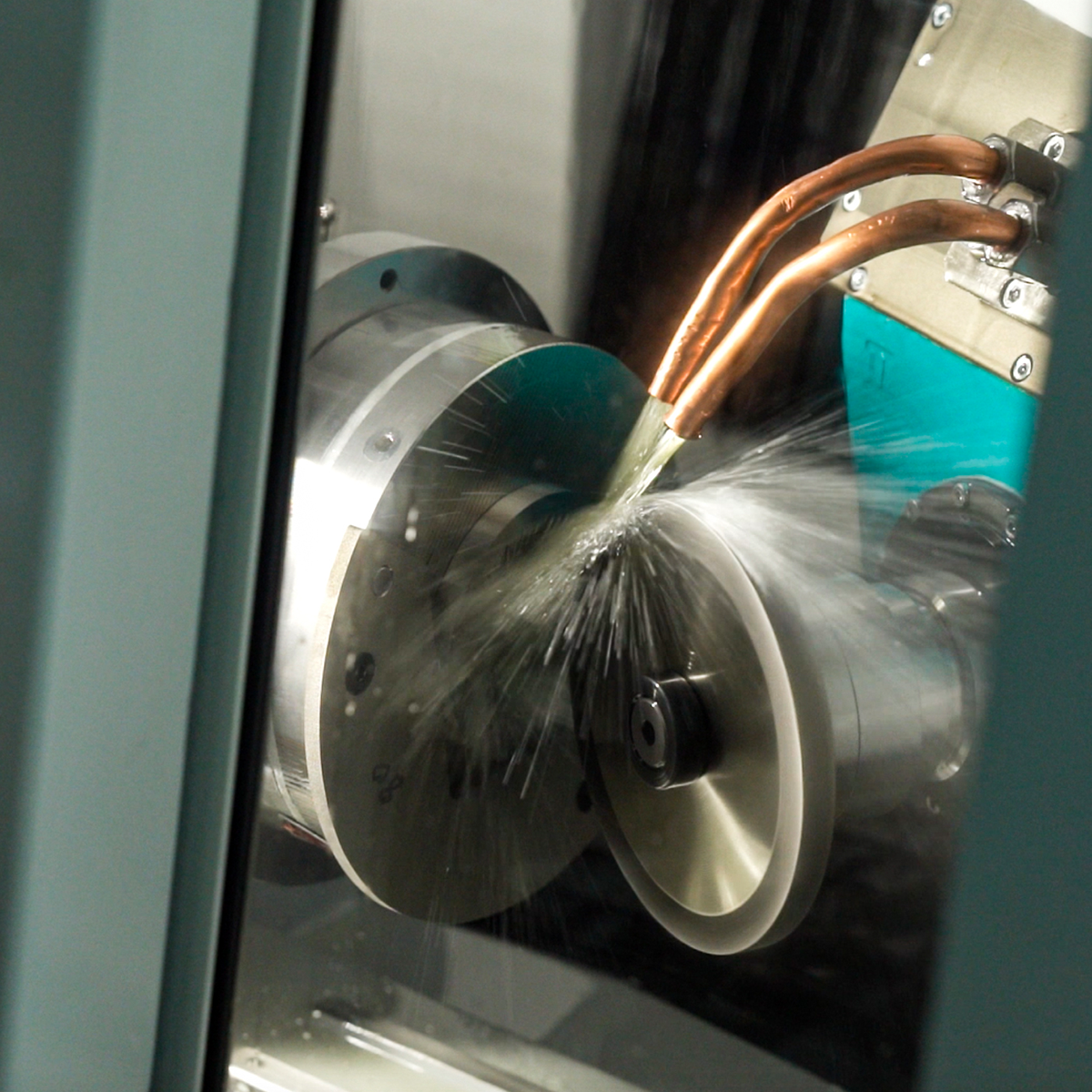

High-temperature heat treatment enhances the burrs' wear resistance.

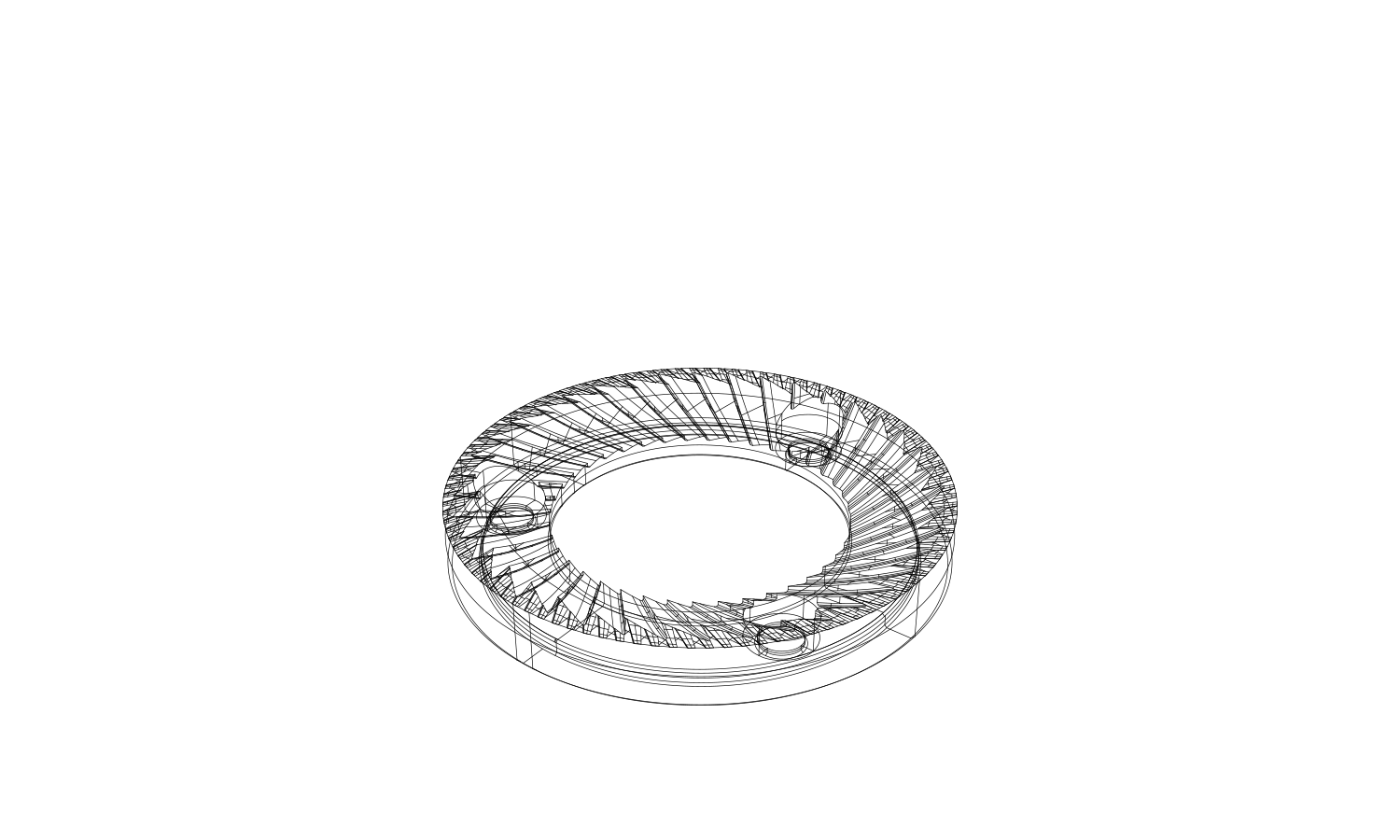

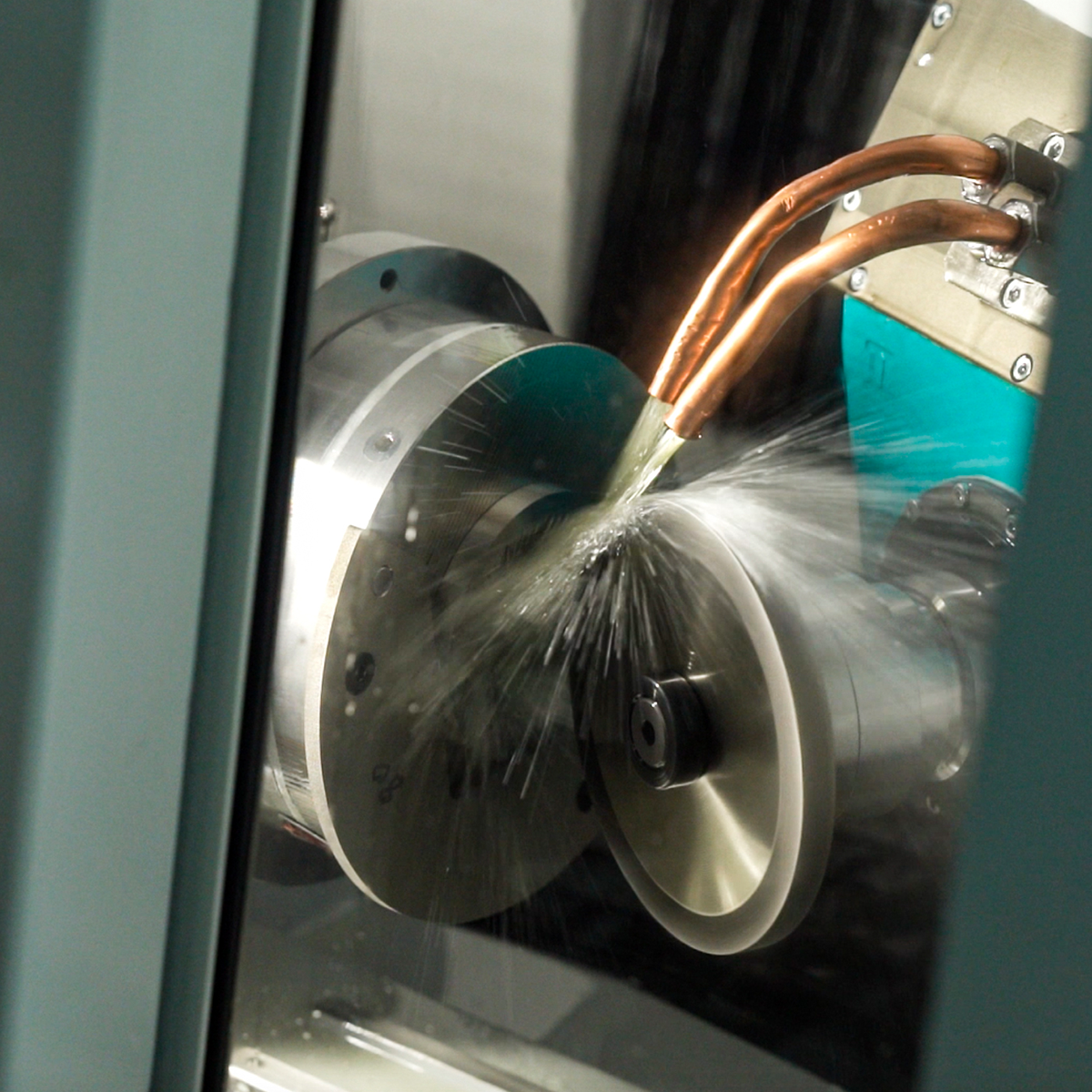

Using 5-axis High-Precision Burrs Processing Machines.

Full process craftsmanship ensures precise dimensions.

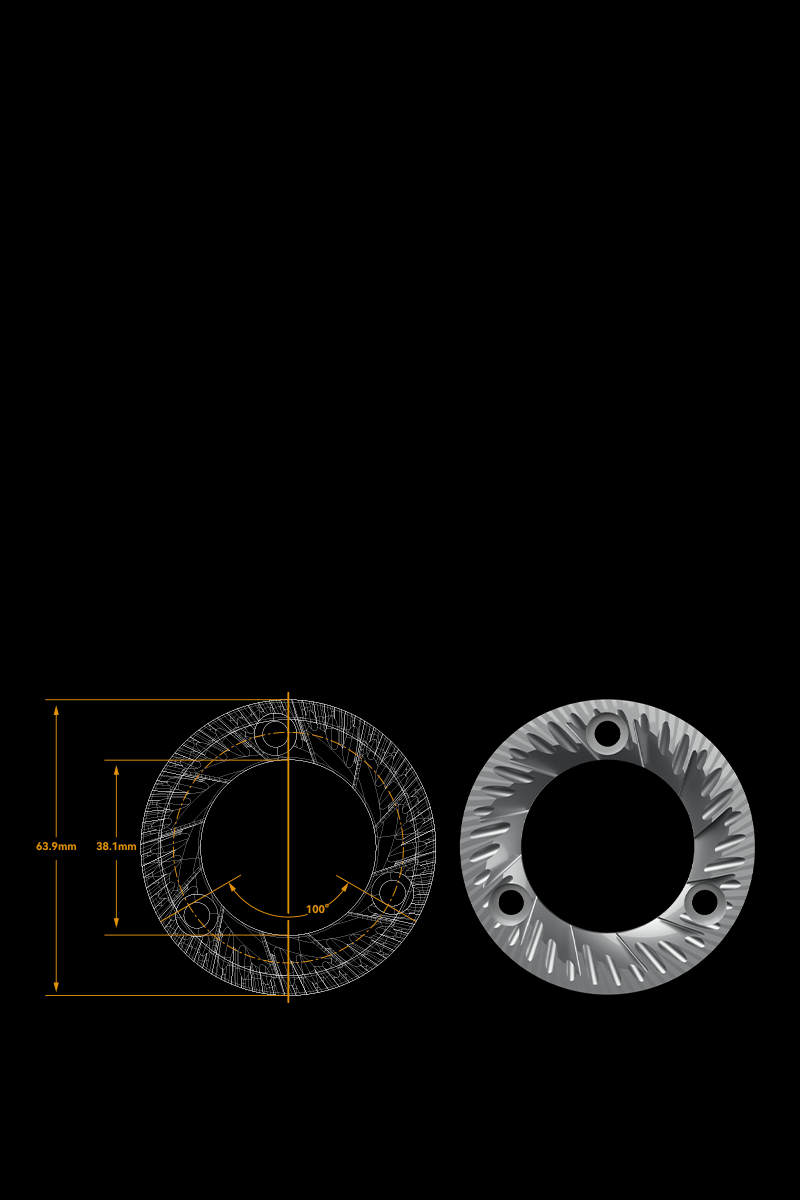

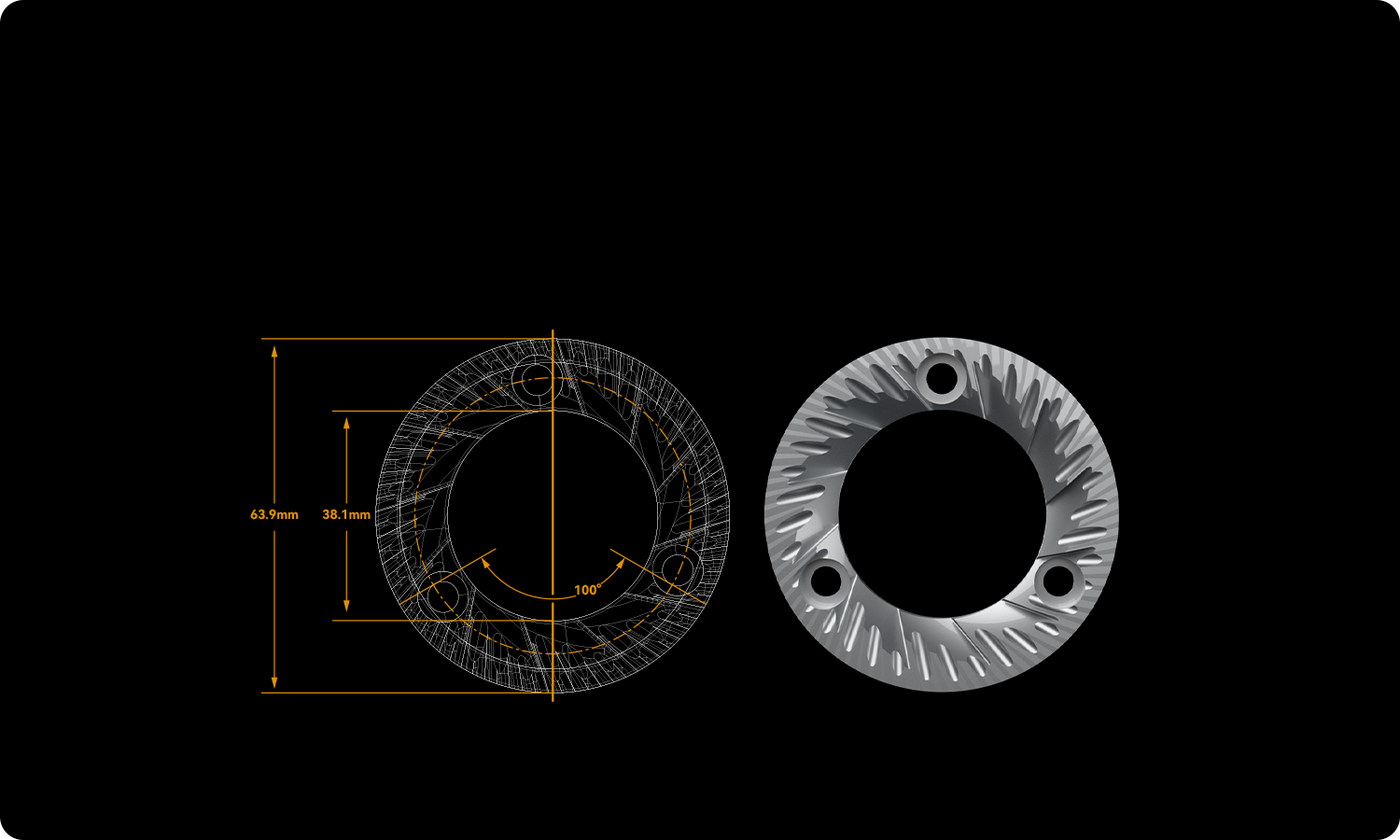

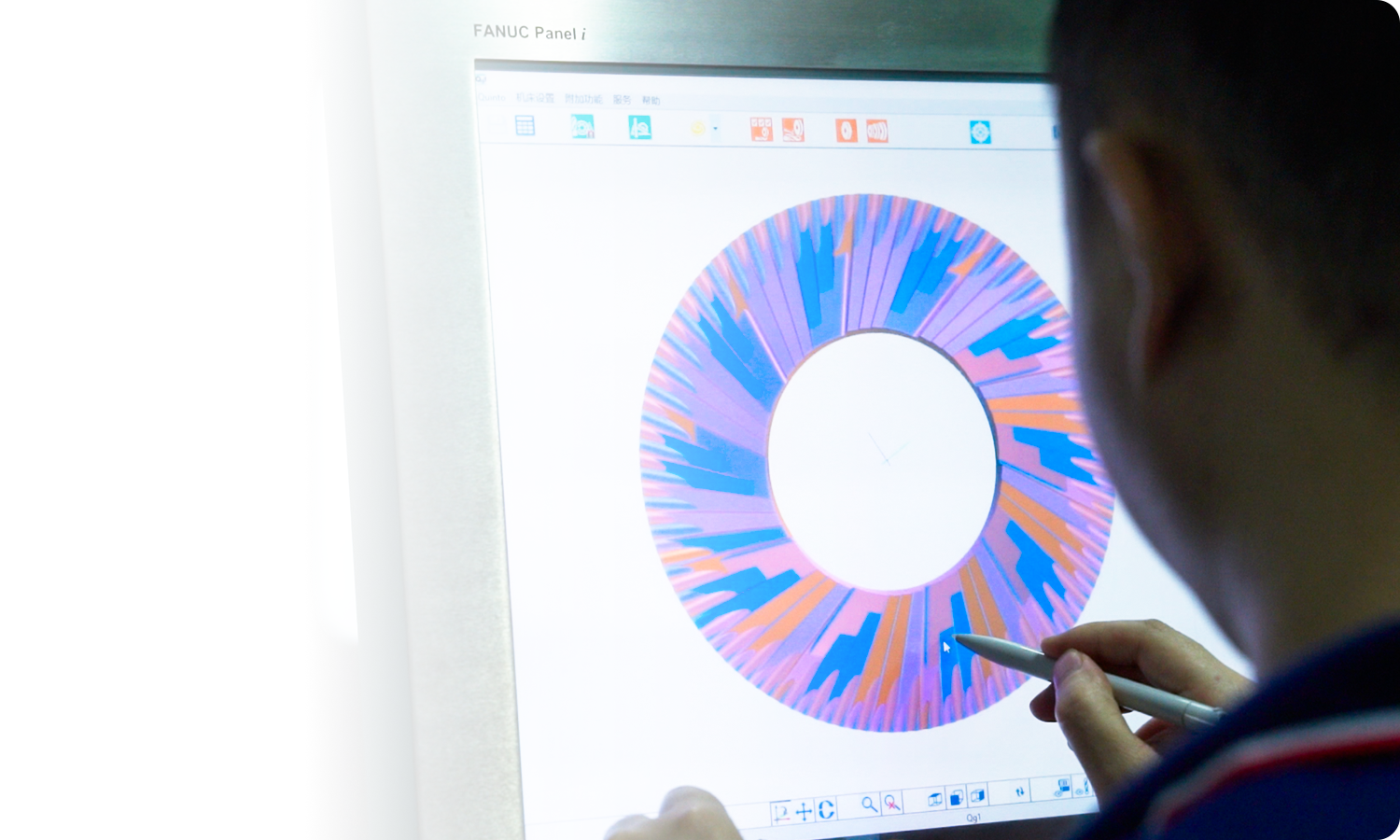

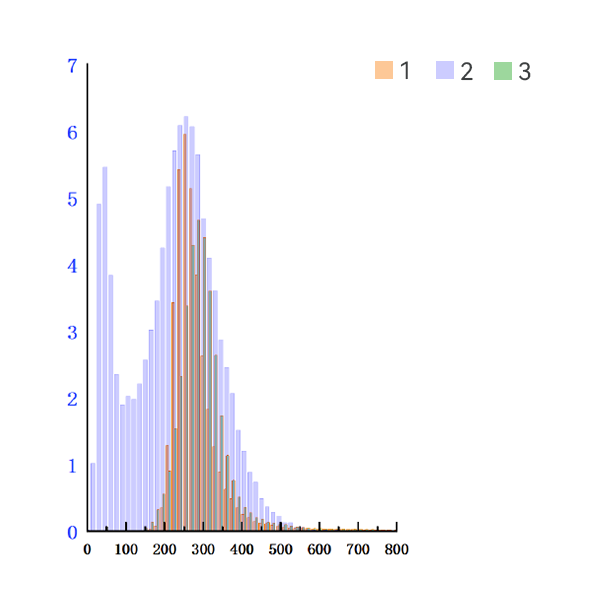

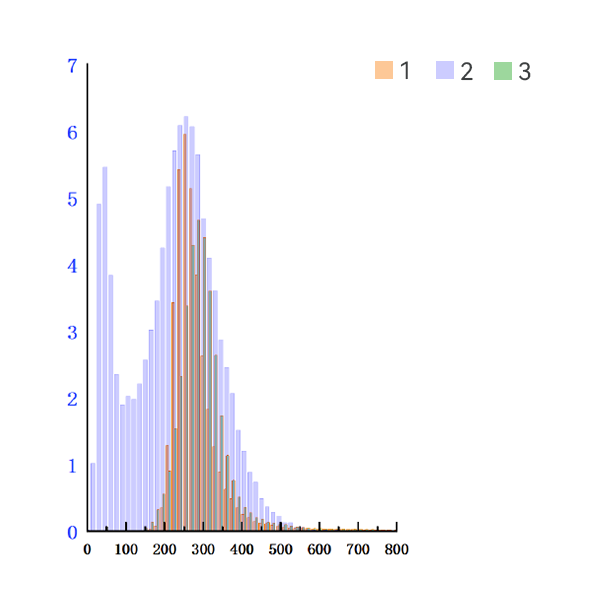

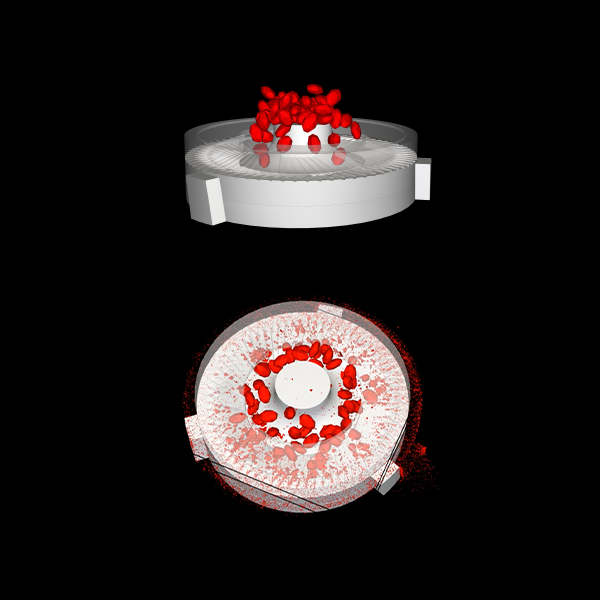

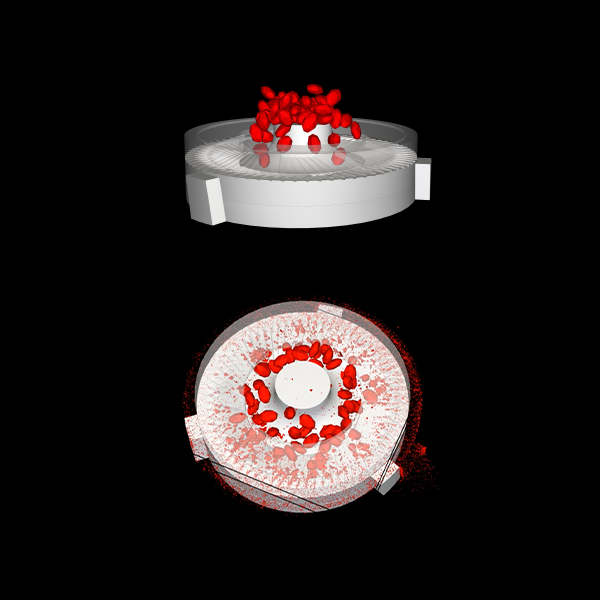

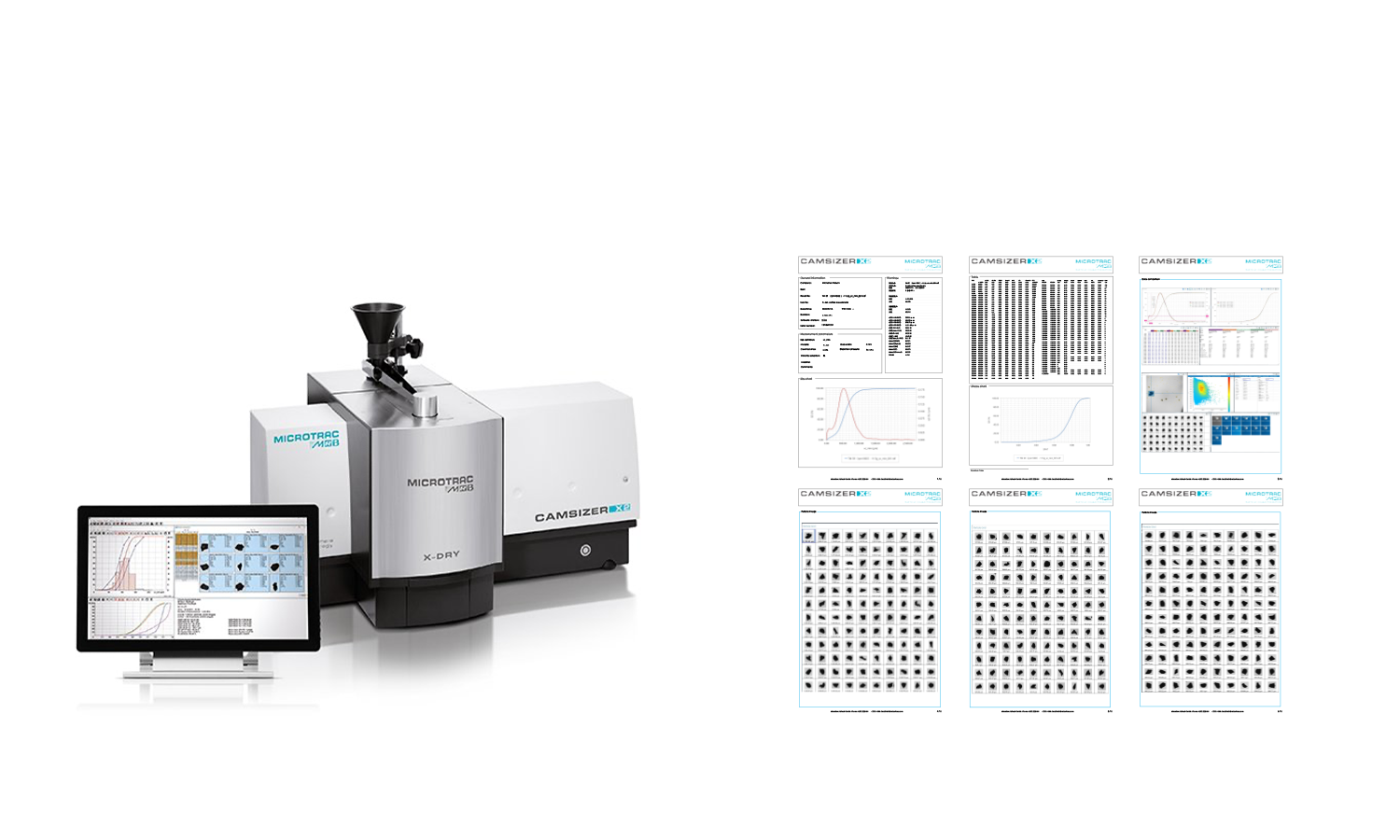

Simulation Design

Optimize burrs' grinding effect with Particle Dynamics Simulation.

Equivalent ball diameter of simulated particles,Relative volume fraction of the actual equivalent particle size class,Simulated particle size

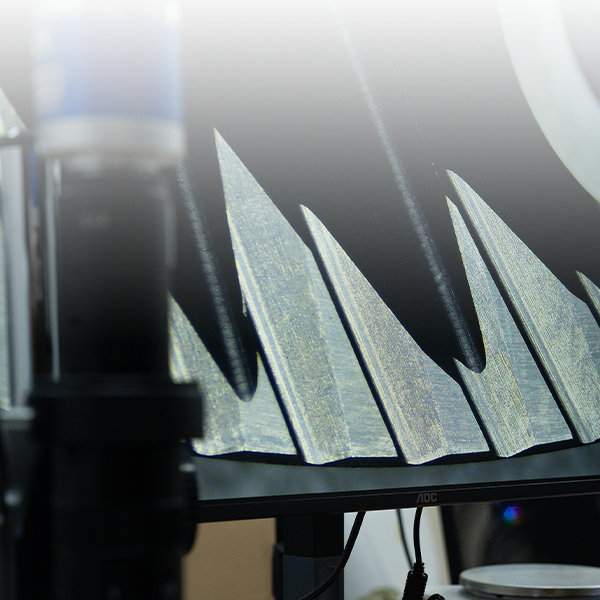

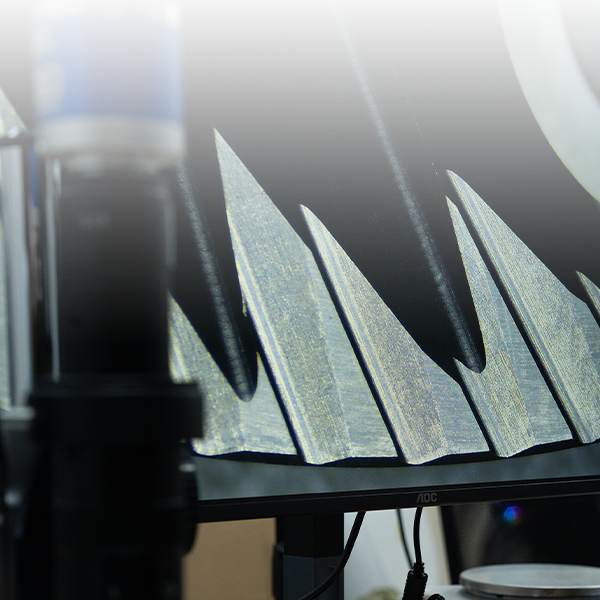

Strict Control For Every Burrs

After production, LeBrew conduct Millimeter-level checks on the burrs.

Only ship it once it meets requirements.

FAQs

If you have any other inquiries or need further assistance, feel free to contact us . We’re here to help!

We provide comprehensive customization services, including size, tooth profile, material, coating, thickness, and branding engraving, ensuring the burrs meet various grinding requirements such as pour-over, espresso, American-style, and cold brew.

We currently support standard sizes of 64mm, 78mm, 83mm, 98mm, and 180mm. Other special sizes can be customized upon request.

We offer a selection of high-performance materials and coatings to enhance the durability, stability, and grinding efficiency of the burrs.

Material options: DC53 cold-work tool steel, tungsten steel (carbide), etc., suitable for high wear resistance and high-strength applications.

Coating options: TiAlN (Titanium Aluminum Nitride), DLC (Diamond-Like Carbon), both of which enhance conductivity, reduce coffee powder adhesion, and improve particle distribution consistency.

Yes, we offer laser engraving for brand logos, model numbers, and custom markings to help brands create unique products with greater market recognition.

For standard sizes (64mm, 78mm, 83mm, 98mm ), the MOQ is 200 pieces.

For special sizes or unique tooth profiles, the MOQ is 500 pieces. Please contact us for further details.

The design confirmation and sample testing phase typically takes 2-4 weeks, while mass production requires approximately 4-6 weeks. The total production lead time is generally between 6-10 weeks, depending on the complexity of customization and production scheduling.

Yes, we can provide samples for testing. Sample production is usually small-batch, and additional costs may apply. If a bulk order is placed after testing, part of the sample cost may be deducted from the total order.

Customers need to provide the specifications of their grinder's burr mounting system (such as center hole diameter, screw hole positions, etc.). We will precisely match the specifications and provide CAD design files for confirmation before production.

You can reach us via email at or through our social media channels @lebrewtech. Our team will respond as soon as possible and provide professional support.