The Science Behind Agtron Roast Analyzer and Coffee Roasting Control

Abstract

The essence of coffee roasting lies in a series of complex, heat-induced chemical reactions, the most visually apparent of which is the color transformation of the coffee beans. To enable quantifiable control over the roasting process, the Agtron roast analyzer—also known as the Agtron Scale or coffee roast meter—was developed and has become an industry-standard tool for standardized roast evaluation.

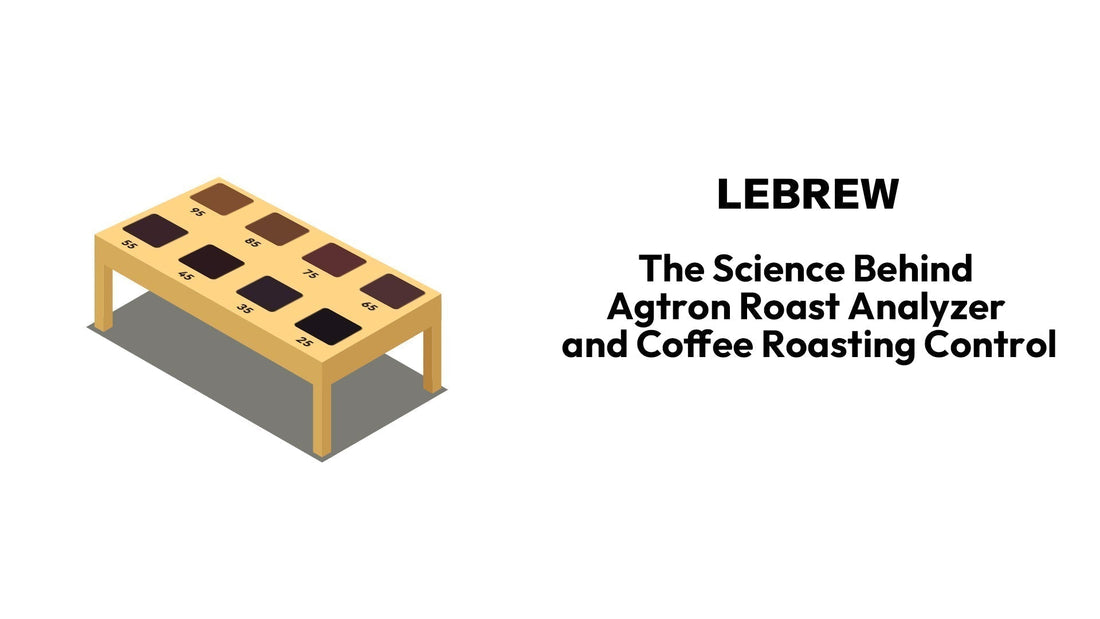

The Agtron analyzer operates based on near-infrared reflectance spectroscopy. When visible and near-infrared light is directed at a coffee sample, surface compounds such as caramelization byproducts and melanoidins selectively absorb specific wavelengths. The remaining unabsorbed light is reflected back and captured by the built-in near-infrared optical sensor. These reflected signals are then processed through a preset algorithm and translated into a numerical Agtron score ranging from 0 to 150:

Lower values → lower reflectance → darker roasts (e.g., Agtron #35)

Higher values → higher reflectance → lighter roasts (e.g., Agtron #95)

The Specialty Coffee Association of America (SCAA) has adopted this system to define its widely recognized coffee roast classification standards. By precisely quantifying roast levels through Agtron values, roasters can not only ensure batch-to-batch consistency but also develop correlations between color and flavor, thus enhancing both the scientific rigor and controllability of the roasting process.

1. What Is the Agtron Scale and Why Is It Important?

1.1 Fundamentals of the Agtron Color Scale

-

Higher values (e.g., 80–100) indicate lighter roast levels

-

Lower values (e.g., 25–40) indicate darker roasts

1.2 Why Is “Quantification” Important in Coffee Roasting?

-

Consistency ControlIn commercial roasting operations, the same roast profile may be repeated dozens or even hundreds of times per day. With tools like the Agtron Coffee Roast Analyzer or Agtron Blockage Monitor, roasters can ensure a high degree of batch-to-batch consistency, enhancing product stability and customer experience.

-

Flavor Replication & DevelopmentDifferent Agtron values correspond to different flavor characteristics. For instance, coffees roasted to an Agtron range of 70–80 tend to retain more acidity and floral notes, while those below 45 highlight bitterness, sweetness, and body/oil content. By establishing a correlation chart between Agtron values and flavor profiles (often referenced alongside an Agtron Coffee Color Chart), roasters can effectively replicate or refine target flavors.

-

Professional Evaluation & Competition StandardsIn prestigious events such as the Cup of Excellence or World Coffee Events (WCE) competitions, Agtron values are often required when submitting samples. Providing quantitative data from certified colorimeters—such as an Agtron Analyzer or Agtron Color Meter—is essential to increase credibility and meet industry standards for professionalism.

2.Measurement Principle

2.1 How Does a Roast Color Meter Work? (Technical Explanation)

How to Calibrate an Agtron Roast Color Meter: Step-by-Step Guide

3.1 Standard Calibration Procedure

-

Use a lint-free cloth to clean the optical measurement window and the surface of the calibration tile (reference disc).

-

Remove any coffee residue, oils, or moisture that could interfere with light transmission.

-

Insert the supplied Agtron calibration tile (typically a ceramic reflective disc) into the sensor window.

-

Navigate to the device’s menu and initiate the “Zero” or “Calibrate” function to establish the baseline reference signal.

-

Measure a standard calibration tile with a known Agtron reference value.

-

If the actual reading deviates by more than ±1.5 Agtron units from the nominal value, repeat the zeroing process.

-

Use a control sample of roasted coffee beans with a known Agtron value to verify accuracy under real-world conditions.

-

This step ensures consistent and repeatable results during actual sample analysis.

3.2 Recommended Calibration Frequency (Based on Use Case)

| Use Case | Recommended Calibration Frequency |

|---|---|

| Laboratories / Testing Facilities | Calibrate before each use |

| Roasting Facilities (Standard Usage) | Calibrate once every 3 months |

| High-Volume or Multi-Shift Operations | Calibrate once a month |

| After Abnormal Readings or Lamp Replacement | Calibrate immediately |

3.3 Why Is Regular Calibration Important?

-

To prevent systematic errors caused by aging optical components

-

To improve consistency across coffee roasting batches

-

To ensure the reliability of Agtron values for international competitions or commercial deliveries

-

To meet the precision standards required by certified instruments such as the Agtron coffee scale

Common Sources of Measurement Errors and How to Avoid Them

-

During roasting, coffee beans may heat unevenly, resulting in color differences between individual beans—sometimes varying by as much as ±10 Agtron units.

-

Relying on a small sample or just a few representative beans can easily lead to misleading conclusions.

-

Recommendation: For each measurement, randomly sample at least 20 grams of coffee beans and mix thoroughly before testing. This ensures a more representative and reliable color reading.

-

When using an Agtron device, whole bean measurements reflect the caramelization level on the bean’s surface, while ground sample readings reveal the actual roast development inside the bean.

-

The difference between these two values—known as the Roast Delta (RD value)—is a critical indicator of roast uniformity and flavor complexity.

-

Examples:

-

Light roasts typically show an RD value of 10–15

-

Medium to dark roasts tend to have an RD value below 5

-

-

Ignoring RD analysis may lead to undetected roast defects, which is especially crucial in the context of specialty coffee.

-

When preparing ground coffee samples, many people habitually press and level the grounds firmly, making the sample more compact.

-

This compression increases light reflectance, which can result in artificially high (lighter) Agtron readings. Recommendation: Gently level the surface of the sample without applying pressure—aim for a flat surface, not a compressed one.

-

Oils and fine particles generated during roasting can easily accumulate on the sensor window—this is especially noticeable when measuring dark roast samples.

-

Grease buildup alters the light’s refraction, leading the system to misinterpret the color as lighter than it actually is, resulting in an artificially high Agtron value.

-

After each use, wipe the sensor's glass window with anhydrous ethanol to ensure it remains clean and transparent.

-

For frequent users, a full maintenance routine is recommended at least once a week.

Agtron value reference table

Recommended equipment:

Have Questions or Suggestions?

If you have any feedback or would like to know more, feel free to contact us at:

service@lebrewtech.com